The Watling Insulator

by Larry Larned

Reprinted from "INSULATORS - Crown Jewels of the Wire", July 1982, page 7

Have you seen a Watling insulator

lately? And now you're asking, "What was that?" Even an ad appearing

in the September 1954 issue of Popular Mechanics showing this insulator in use,

didn't identify it as a Watling. Recently while poring through a stack of aging

Popular Mechanics, I came across a Bell Lab ad announcing a new concept for open

wire pole line construction: the climbless pole. The ad also described a new

insulator developed for the climbless pole, as shown in figure 1.

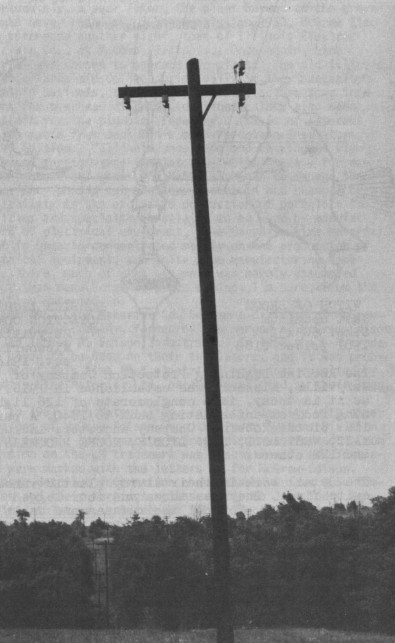

Figure 1

The Watling in use

Chester, New Jersey

|

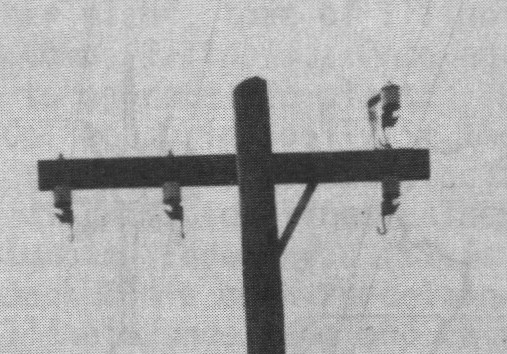

Magnified section from Figure 1 |

And so, with

the courtesy of Bell Laboratories, I can relate to you the circumstances

surrounding the "limited edition" Watling insulator.

As collectors, we

understand the long period of development which insulators have undergone and,

in particular, the many schemes invented to hold the line wire. The Barclay,

Blackburn, Brooks, Buzby, Cutter, Lewis and others, even the rams horn, had its

place. As a matter of fact, the Watling is a kind of mechanical rams horn.

The

tie wire used on early telegraph insulators was adapted for telephone

insulators, but proved troublesome on the more numerous and smaller telephone

insulators. Many schemes were devised, some were patented, and few were actually

placed in service. The introduction of twisted pair wire about 1900 required a

new insulator, the CD 115 designed with deep grooves to hold a single line

consisting of a wire pair with its own twisted pair tie wire as shown in figure

2. The CD 115 became the Bell System exchange standard, and its deep double

groove feature adapted it to many situations found along the exchange line, such

as transpositions, dead-ends, subscriber drops, etc.

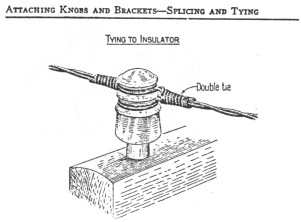

Figure 2

The CD 115 with twisted pair

wire AT&T Standard - 1913

Just as the CD 115 became

the standard on exchange lines, the CD 154-155 became the standard on toll

lines. Both insulators continued to use tie wires, a technique requiring skilled

work by linemen climbing each pole.

During the years following World War II, Ma

Bell was faced with a tremendous expansion of local telephone service,

particularly in rural areas. To help meet this expansion, Bell Labs set out to

develop a new open wire pole line system. This system was to be easily erected

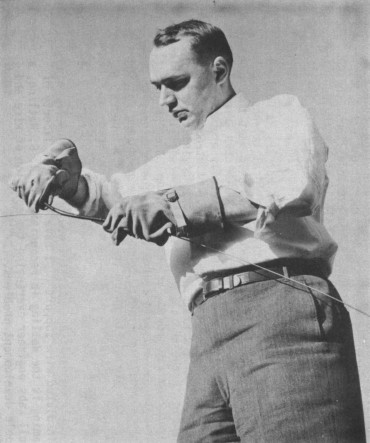

from the ground and operated with a minimum of maintenance. A key component of

the system was a new type of insulator mounted underneath the cross arm to

facilitate installing the line wire from the ground, as shown in figure 3. The

installation process utilized a wire raising tool designed to perform several

functions: to hold the wire during raising from the ground, to guide the wire

into its support, and to tighten the support after the wire is tensioned, as

shown in figure 4.

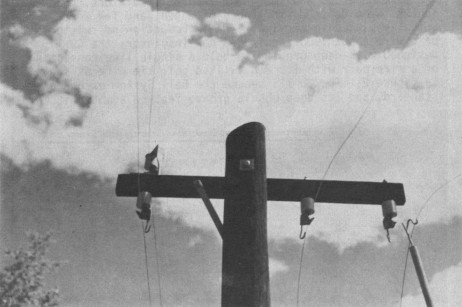

Figure 3

Mounting Hardware

Figure 4

The wire raising tool

The generic name for the new type of insulator was

"insulated wire support". I have taken the liberty of naming it the

Watling in recognition of R. G. Watling, a Bell Labs engineer overseeing the

solution of wire and cable development problems.

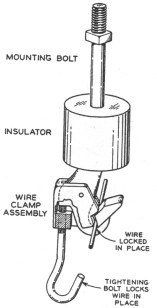

Fig. 5 -- Drawing of the new insulated

wire support, showing parts.

The Watling insulator consists

of three major components: The mounting bolt, similar to the steel pin cob

support for glass insulators; the insulating medium; and the wire clamp

assembly; as shown in figure 5. The insulating medium consists of styrene polyester resin. The metal parts are molded into the styrene in the form of a

cylinder. Contrary to the water shedding skirts of all those Hemi 42's out

there, the Watling is not designed for a "dry path", but depends on

rain for keeping its surface clean. The wire clamp assembly made of aluminum is

essentially a hook with keeper and a steel locking screw. As the line wire

enters the hook, it pushes the keeper aside and drops into the slot. The keeper

then restores and traps the line wire, but allows it to move freely through the

hook longitudinally to permit tensioning.

Figure 6

Raising the pole!

Figure 7

Placing vibration damper

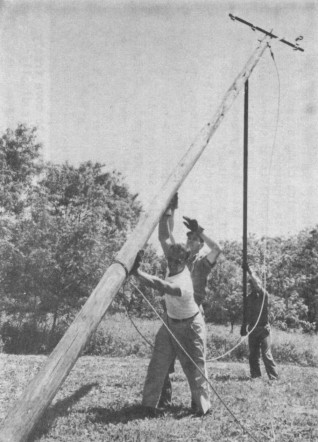

All of the pole hardware, including

insulators, are attached to the pole on the ground. Now for the great moment --

raising the pole! Three strong men are called on to perform the honors, as shown

in figure 6. The pole is guyed, and line wires lifted into place. Just prior to

lifting, plastic vibration dampers are placed on the wires in each span, as

shown in figure 7. Vibration dampers, by the way, are standard fare for other

types of open wire systems, too -- by flexing they absorb wind induced energy in

the wire and prevent high frequency, low amplitude vibrations which could result

in injury to the line wire at its point of support.

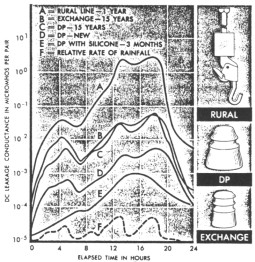

Figure 8

Typical dc leakage data taken during a rain storm.

Curves show how leakage varies with design, age,

and storm intensity. Insets at right show

appearance of insulators depicted in curves.

Field trials for the new

system and its insulator were held in New Jersey, Virginia, Colorado, and

Louisiana under conditions designed to test construction techniques, fatigue

endurance qualities and insulating capabilities. Sorry to say, the Watling

flunked the third section of its test. As the graph in figure 8 shows, the Watling fared badly when tested for leakage during rainstorms. Designed without

a "dry path" for its conductor, the Watling has about one hundred

times more leakage than the CD 155 or CD 115. A further aspect of the test is

interesting to us as insulator collectors -- notice how age affected the leakage

characteristics on both glass insulators. Leakage on the DP, CD 155 increased

five to ten times after 15 years of exposure.

The field trials and lab testing

were enough to convince the policy makers at Bell Labs not to implement the

"new type open-wire pole line system" for use as a standard in rural

areas. Instead, cable has replaced most of the rural open wire mileage

maintained by Ma Bell.

Incidentally, for our son's birthday, we recently

purchased a set of Tonka telephone trucks complete with cable reels, men

working, signs and, of course, plastic telephone poles with cross arms. I

examined the telephone poles hoping to find a new type of insulator! What do you

suppose I found? Why, of course, something mounted under the cross arm

resembling a hook. What was that?

|